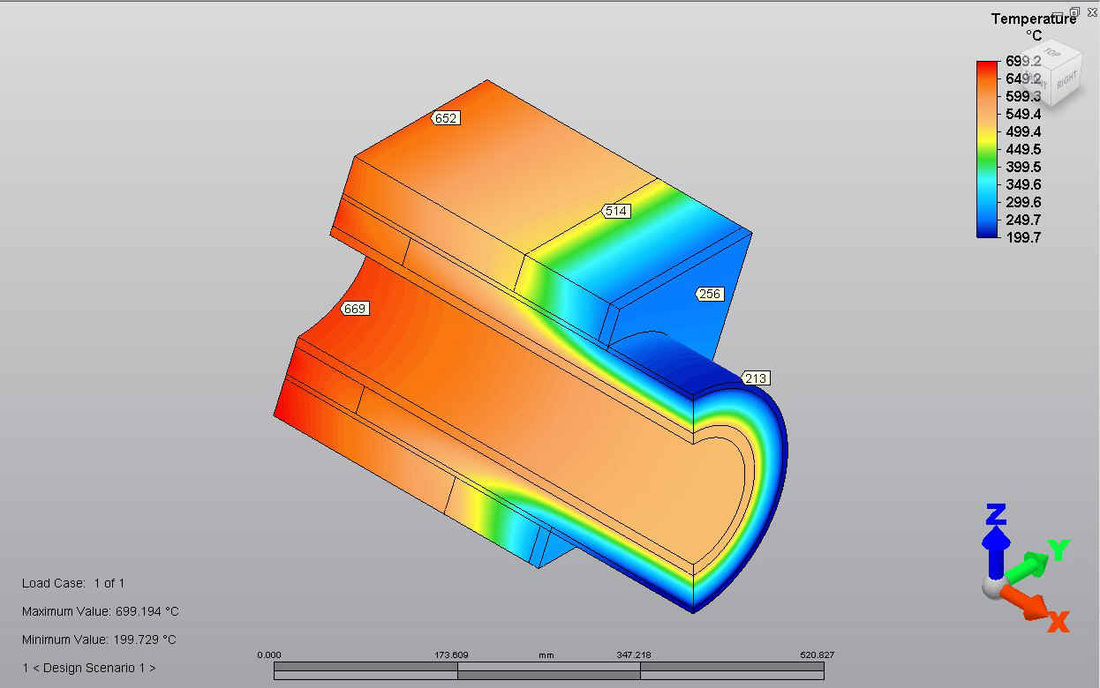

Thermal Process Design

|

CBE is a specialist at thermal process design and air pollution control systems. We will provide you with a full range of services including process development, providing complete sets of detailed plans and specifications, project management, troubleshooting operational problems and field engineering, in addition to stack testing, emission control systems, CEMS and operator training.

To learn more click on the links below:

Activated Carbon

Sewage Sludge Incineration CAA Section 129 Compliance Sludge Cake Receiving Fat, Oil, and Grease (FOG) Applications Engineering service capabilities include:

|