Retrofits | Stack Testing | Permitting | Training | Analysis | More Services

Equipment RetrofitsDue to furnace longevity, most industrial and municipal facilities have been operating without modifications to their equipment since original construction, even if this was decades ago. However as federal and state air regulations become more restrictive, process and equipment changes become necessary but difficult due to plant layouts. For these situations, CBE specializes in designing equipment retrofits to minimize plant footprint changes while providing any necessary equipment for achieving new emission regulations. With every facility being unique, our experienced staff can help you determine what your facility needs to comply with these new standards.

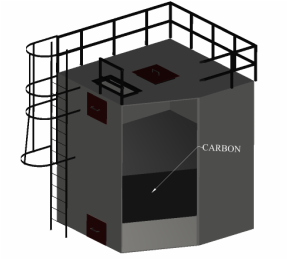

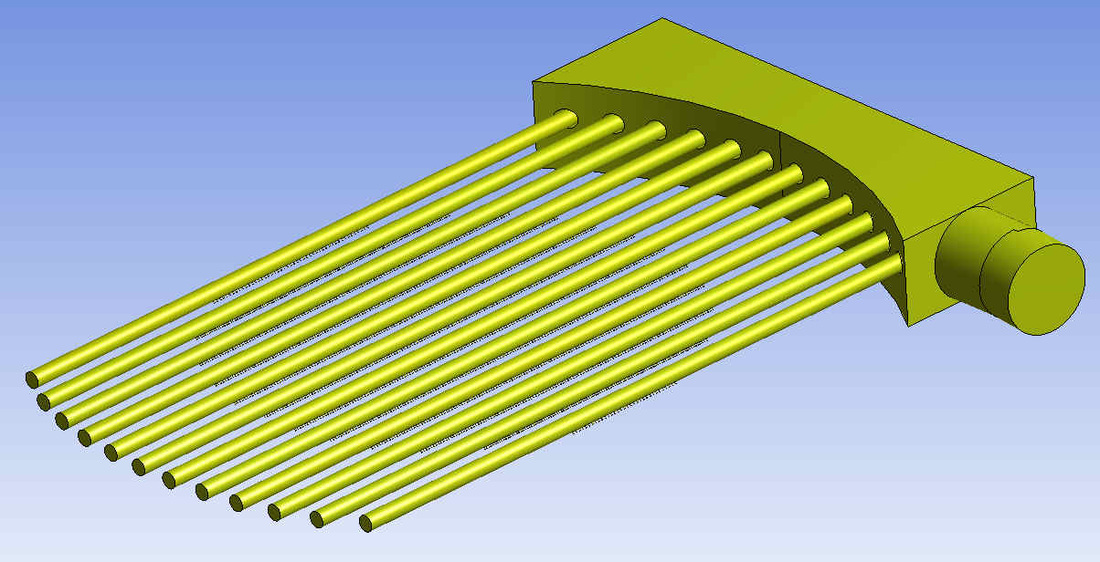

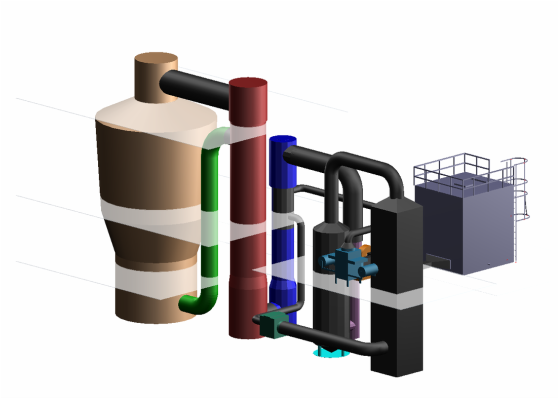

Mercury Adsorbers On March 21, 2011 the Environmental Protection Agency (EPA) published new standards of emission limits for 9 pollutants for new and existing sewage sludge incinerators (SSIs) in 40CFR60 subparts MMMM & LLLL. Particularly, meeting the new emission limits for mercury will require additional air pollution control equipment for most facilities. The current solution for this problem is the addition of an activated carbon based mercury scrubber / adsorber. Such devices come in 2 forms, Powdered Activated Carbon (PAC) injection or an activated carbon column. CBE has done extensive research into these technologies and has specified designs for our clients to add mercury absorbers to their air pollution control equipment. These custom retrofit designs have utilized the available space in the plant layout to be able to add the additional requirement equipment into the incineration systems. Scrubber Modifications CBE’s equipment retrofitting knowledge also includes auxiliary equipment to the incinerator, with a particular recent example being scrubber modifications. Due to seasonal spikes in sulfur dioxide concentrations, a client needed improved scrubber efficiency beyond their current equipment to reach the new emission limits. CBE conducted extensive research into viable alternatives and has specified a new multi-venturi scrubber which is able to fit into the existing tight space of the previous scrubber while providing better scrubbing efficiency. Tuyere Pipe Systems CBE has extensive experience designing an innovative tuyere pipe system for air distribution. This design can be retrofitted to existing fluidized bed incinerators that currently utilize a windbox design with refractory dome and tuyeres while being operationally the same. Benefits to this redesign include easier maintenance and a longer life expectancy, both leading to substantial financial savings. |