Profile | Directions | Careers

Company Profile

|

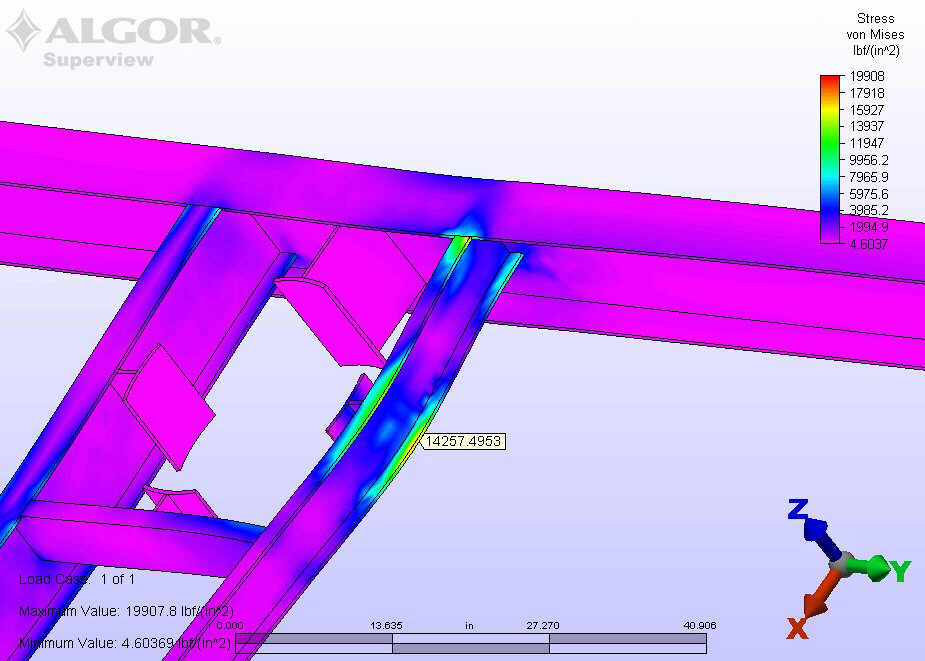

Chavond-Barry Engineering Corp. was formed in 1983 to offer independent consulting services for the specification and use of process furnaces and their auxiliaries. Chavond-Barry is exceptionally well-versed in fluid bed incinerators, multiple hearth furnaces and shaft kilns. When special requirements cannot be met by a commercially available furnace, CBE will provide fully detailed custom design plans for unique furnaces.

CBE is a firm of licensed professional engineers that focuses exclusively on the design and maintenance of industrial furnaces. Our specific dedication and long experience in this field has helped clients across North America stay on the cutting edge of new technology. CBE’s engineers have a broad range of education and training, in addition to decades of field experience. For example, our experience with air pollution controls, permitting, air modeling and stack testing of incinerators enables us to minimize modifications and additions to your plant to meet changing air quality regulations and specify the most cost-effective air pollution equipment for your new plant. On March 21st, 2011 the EPA published new standards for existing and new Sewage Sludge Incinerators (SSI’s) in 40CFR60 subparts MMMM & LLLL respectively. These new standards set strict numerical concentration emissions limits for: Cadmium, Carbon Monoxide, Hydrogen Chloride, Lead, Mercury, Nitrogen Oxides, Particulate Matter, Polychlorinated Dibenzo-p-dioxins & Polychlorinated Dibenzofurans, and Sulfur Dioxide. The new regulations are schedule to take effect in March 2016. For most existing fluidized bed sewage sludge incinerators, meeting the mercury emission standard of 40CFR60 subpart MMMM stands out as being the major point of concern. CBE has performed extensive research into the available control technologies and manufacturers and is actively specifying several mercury adsorption systems for clients in 2015. As consulting engineers, Chavond-Barry can fill a variety of roles from project inception through completion, and long after to assure continuing optimum plant operation, including: Preliminary Evaluations

Procurement and Construction

Post-Construction or Existing Plants

|

|