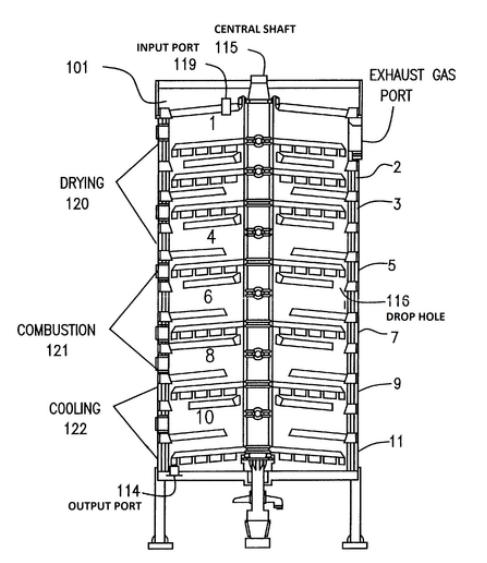

Multiple Hearth Furnaces

See also Afterburner Options | Flue Gas Recirculation

|

A Multiple Hearth Furnace consists of a series of circular hearths, positioned in a column and enclosed in a refractory-lined steel shell (See MHF diagram below). A vertical rotating shaft through the center of the furnace has rabble arms which moves the feed material in a spiral path across each hearth, until it passes through drop holes to the hearth below. After it passes through each hearth, the final product is discharged through an outlet. Heated gases flow against the material current in order to heat the charge to reaction temperature and obtain the desired result. In some applications, such as incineration, combustion of feed material supplies the heat. In other cases, such as mineral roasting, it is furnished by combustion of auxiliary fuel in burners on certain hearths (direct firing), or in a separate combustion chamber (indirect firing).

CBE has extensive experience in the implementation and optimization of multiple hearth furnaces for a variety of applications including: carbon activation and regeneration, sewage sludge incineration, mineral calcining, and many other unique applications. Our capabilities include providing process and instrumentation drawings and/or detailed plans and specifications for your entire plant. Click the button below to see the "Method and Apparatus for Operating a Multiple Hearth Furnace" patent developed and written by CBE President Louis T. Barry to learn more ..

|

A CBE illustration of an out-hearth and an in-hearth typical of a Multiple Hearth Furnace. The out-hearth illustrates the use of a back rabble arm for improved material mixing on the hearth.

Rabble arm demonstration.

|